Robust Hydraulic Backhoe Loader for Diverse Construction Needs

Strong Power: 75kW Cummins engine, >25KN lifting, 50KN digging, 70–75KN traction.

Versatile Use: Dual buckets, 4340mm digging depth, 5481mm radius for multi-tasking.

Easy Maneuvering: 4300mm turning radius, 500mm ground clearance, compact design.

Durable Build: 7840kg weight, 180° bucket rotation, robust components.

Long Operation: 155L hydraulic + 100L diesel tanks for extended work time.

Key Features

- Enlarged cab with safety glass – bright, spacious, excellent visibility

- Adjustable seat – ergonomic support, comfortable for long shifts

- Integrated instrument panel – water temp, oil temp, current clear at a glance

- Brand-name hydraulic components – main pump offers long life & high efficiency

- Hydraulic steering – easy operation, precise control

- Hydraulic travel system – paired with renowned engine for strong power

- Well-designed fuel tank – convenient refueling, extended runtime

- Full functionality – combines all features of mini excavators & loaders

- Excellent overall performance – high operational efficiency

- Multiple attachment options – meets diverse construction needs

Engineering Specifications

Item | Unit | Parameter | ||

Backhoe bucket capacity | m3 | 0.3 | ||

Rated loading bucket capacity | m3 | 1 | ||

Rated Lifting Force | KN | >25 | ||

Equipment weight | kg | 7840 | ||

Backhoe parameter | Max. digging radius | mm | 5481 | |

Max. dump height | mm | 3737 | ||

Radius at the max. dump height | mm | 1084 | ||

Max. digging radius at ground level | mm | 5105 | ||

Digging buckets max. rotating angle | º | 180 | ||

Max. digging depth | mm | 4340 | ||

Max. digging force | KN | 50±10% | ||

Loading parameter | Max. dump height | mm | 2626 | |

Dump reach at max. dump height | mm | 726 | ||

Bucket draw back angle | Transportation position | º | 43.5 | |

Ground position | º | 36.5 | ||

Dump angle | º | 43.5 | ||

Digging depth | mm | 191 | ||

Max. breakout force | KN | >40 | ||

Max. grade ability | º | >30 | ||

Max. traction power | KN | 70-75 | ||

Min. turning radius | mm | 4300 | ||

Wheelbase | mm | 2320 | ||

Front wheel track | mm | 1910 | ||

Rear wheel track | mm | 1820 | ||

Minimum ground clearance | mm | 500 | ||

Total length | mm | 7100 | ||

Total height (Cab) | mm | 2870 | ||

Total Width | mm | 2730 | ||

Bucket width | mm | 2300 | ||

Digging end bucket width | mm | 750 | ||

Hydraulic tank | L | 155 | ||

Diesel tank | L | 100 | ||

Tire | 14-17.5 | 19.5L-24 | ||

Voltage | V | 12 | ||

Engine | cummins 75kw | |||

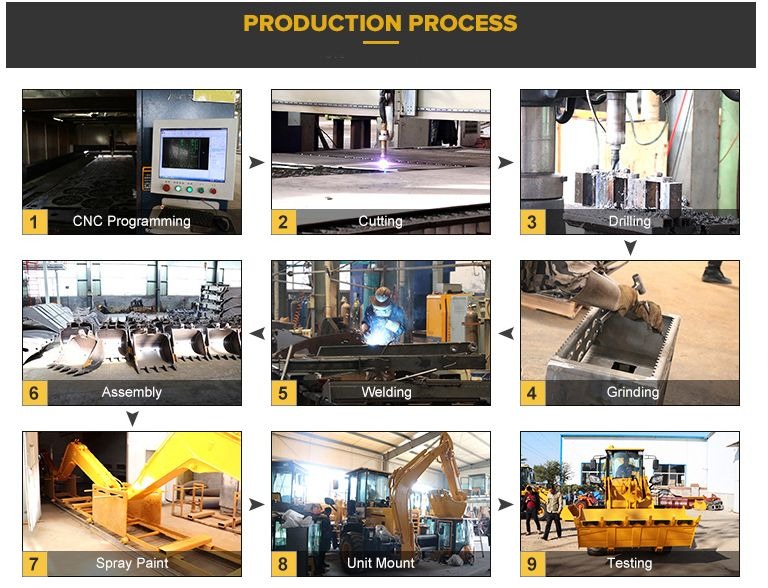

System Configuration Details

Multi-functional Wheeled Excavator Loader

The ultimate combination of digging and loading capabilities in one powerful machine

Product Overview

The wheeled excavator loader is a multi-functional engineering machinery that incorporates excavating and loading into an organic whole. It is rationally distributed and compact, comfortable and convenient to handle, with a small turning radius and high cost performance.

It is widely used in municipal administration, construction, oil fields, water conservancy, forestry, farms, and other fields.

The wheeled excavator loader can be used for excavating, carrying, and leveling, and can also be used flexibly and quickly for the scarp heap and waste residue of large and medium-sized enterprises. It is the ideal model for realizing multi-functional machinery.

Product Advantages

Convenient to handle in tight spaces

Exceptional maneuverability

Superior value for investment

Versatile for multiple industries

Maximized productivity

Tailored to user requirements

Applications

Conclusion

The wheeled excavator loader is a versatile and efficient machine that can be used for a variety of tasks. It is ideal for businesses and organizations that need a machine that can do it all.

With its combination of digging and loading capabilities, compact design, and customizable features, this machine represents the future of multi-functional construction equipment.

Container 40HC 2 units can be installed

1.Standard packing, the machine body is without packing, but the machine will be well fastened and fixed in the container by wire rope.