【Veteran's Tip】Why Your Loader MUST Change Hydraulic Oil Regularly!

💡

The Critical Analogy: Your Loader's Lifeblood

Simply put, hydraulic oil is your loader's "blood" – powering lifts, digs, steering, and lubrication throughout the system. Just as contaminated blood causes health problems, degraded hydraulic oil causes equipment failure.

Hydraulic oil works under extreme conditions daily: temperatures reaching 82°C+ (180°F+) and pressures exceeding 3,000 PSI. This harsh environment causes the oil to gradually "sour" and accumulate contaminants.

Like clean, healthy blood circulating through veins

Optimal viscosity for power transfer

Effective heat dissipation

Proper lubrication of components

Corrosion protection

Contaminant-free operation

Like contaminated, sludgy blood causing system failure

Metal shavings from component wear

Dust and particulate contamination

Oxidation and chemical breakdown

Water contamination (from condensation)

Additive depletion

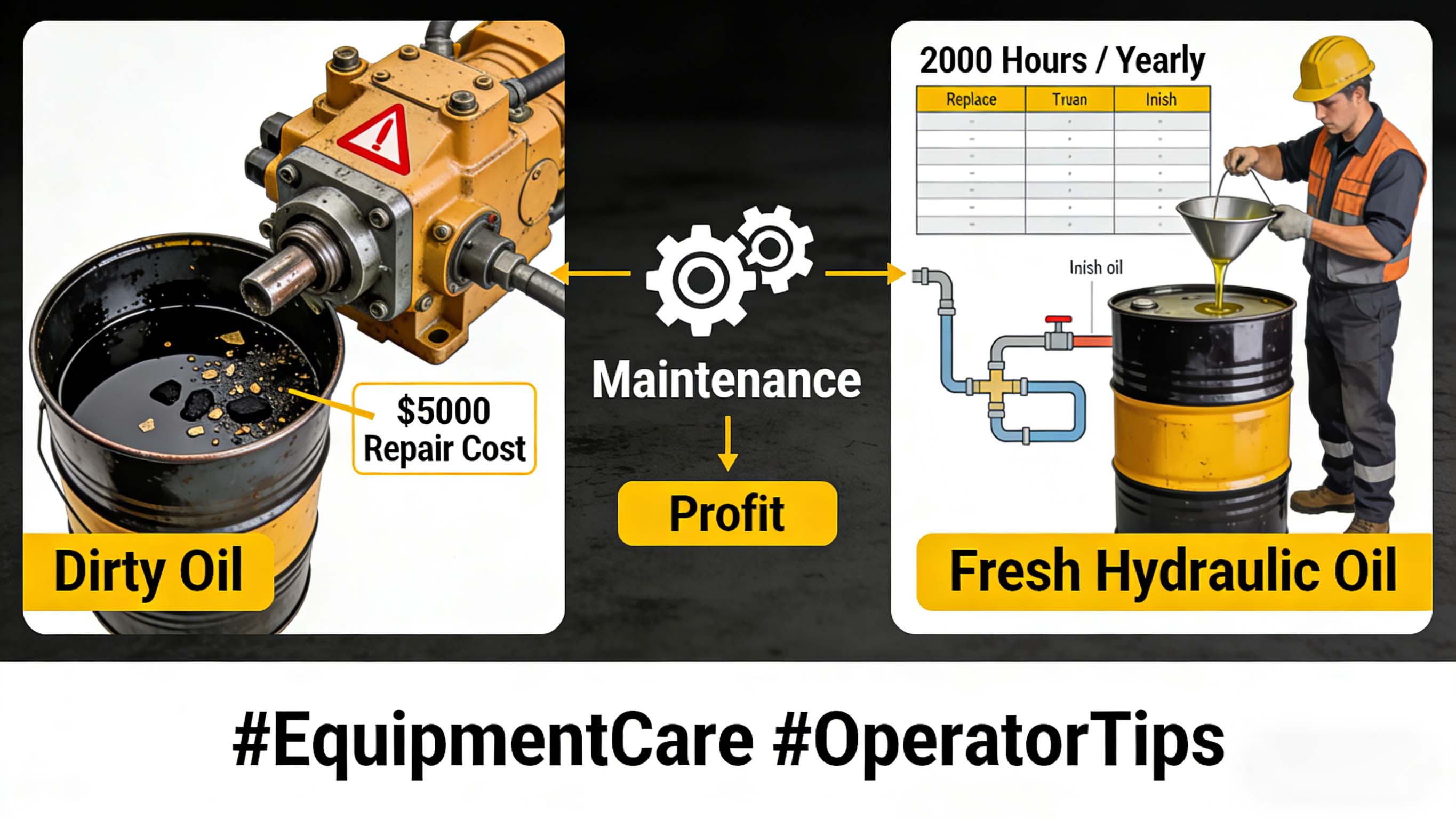

The Dire Consequences of Skipping Changes

Skipping hydraulic oil changes doesn't just reduce performance – it actively destroys your equipment from the inside out.

Weak digging power, unstable steering, slow response times, and reduced lifting capacity.

Abrasive particles grind down precision parts: pumps, valves, cylinders, and seals.

Degraded oil loses cooling ability, causing system overheating and accelerated wear.

Hydraulic pump replacement: $3,000-$8,000. Cylinder rebuild: $500-$2,000 each.

The Real Cost of Neglect

Dirty hydraulic oil acts like liquid sandpaper, grinding away at your most expensive components. The repair bill will make oil changes look like pocket change.

Result: 10-30x higher cost for neglecting basic maintenance

The Smart Maintenance Schedule

Whichever comes first. This isn't a suggestion – it's the minimum requirement for protecting your investment.

When to Change MORE Frequently:

Extreme conditions: Dusty sites, high temperatures, continuous heavy use

Water contamination: If system has been exposed to moisture

Overheating incidents: After any significant overheating event

Visible degradation: Milky, dark, or foul-smelling oil

Simply draining and refilling isn't enough. Follow these steps for maximum benefit: